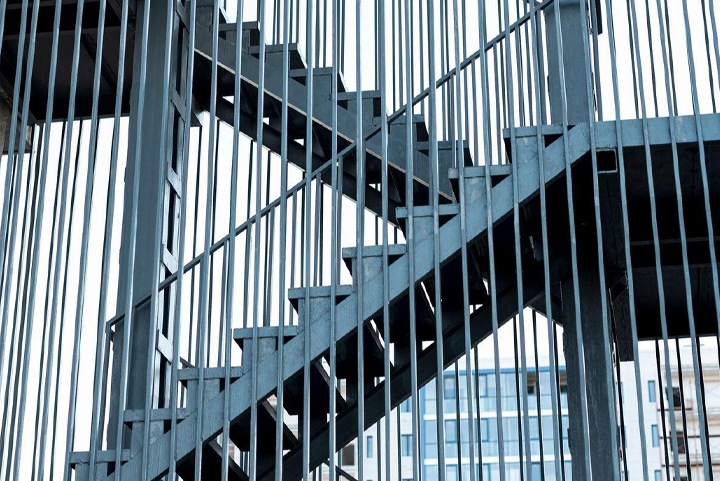

Structural

Steel Detailing

Our engineers know the industry well and are skilled in all projects. We understand the challenges of real-time fabrication and erection and fix issues quickly. Our goal is to create drawings that fabricators can easily use to get the job done.

Miscellaneous

Steel Detailing

Miscellaneous steel detailing requires a lot of independent decision-making, especially in modeling. It also needs good technical knowledge. Our experienced team handles each job accurately and uses the best methods.

Estimation And

Material Take-off

Our fast estimation process includes 3D modeling, material reports, complexity studies, material take-off, and man-hour consumption calculation. We can also provide material take-off if requested by the customer.

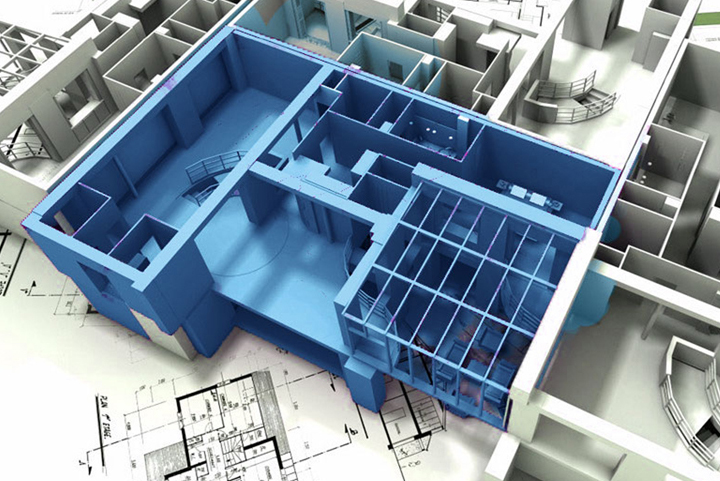

Complete BIM and

CNC support

Technology is moving detailing from 2D to 3D BIM, aiding coordination among detailers, fabricators, and erectors. Cronus Steel uses SDS/2 and Tekla Structures to automate outputs for tools like StruMIS and Voortman.

Research

And Development

R&D is crucial for driving innovation, which is vital for staying competitive. Our dedicated R&D team is continuously exploring ways to automate tasks to ensure precise results and high customer satisfaction.

Our

Latest Work

Our latest steel detailing project showcases our skill with 3D BIM technology. Using SDS/2 and Tekla Structures, we created precise models and automated outputs for smooth integration. This work reflects our commitment to accuracy and quality.